Programme Structure

The FRP++ Master combines the diverse expertise of leading European Higher Education Institutes.

Programme Structure

The Master combines the diverse expertise of leading European Higher Education Institutes in the related fields, namely the University of Minho (UMinho), the University of Girona (UdG), the University of Naples Federico II (UNINA) and Institut National des Sciences Appliquées de Toulouse/University Toulouse III Paul Sabatier (INSA/UT3) to offer an excellent education proposal oriented to a multidisciplinary understanding of structural Composites through the involvement of specialists from complementary fields (engineers, materials science and others).

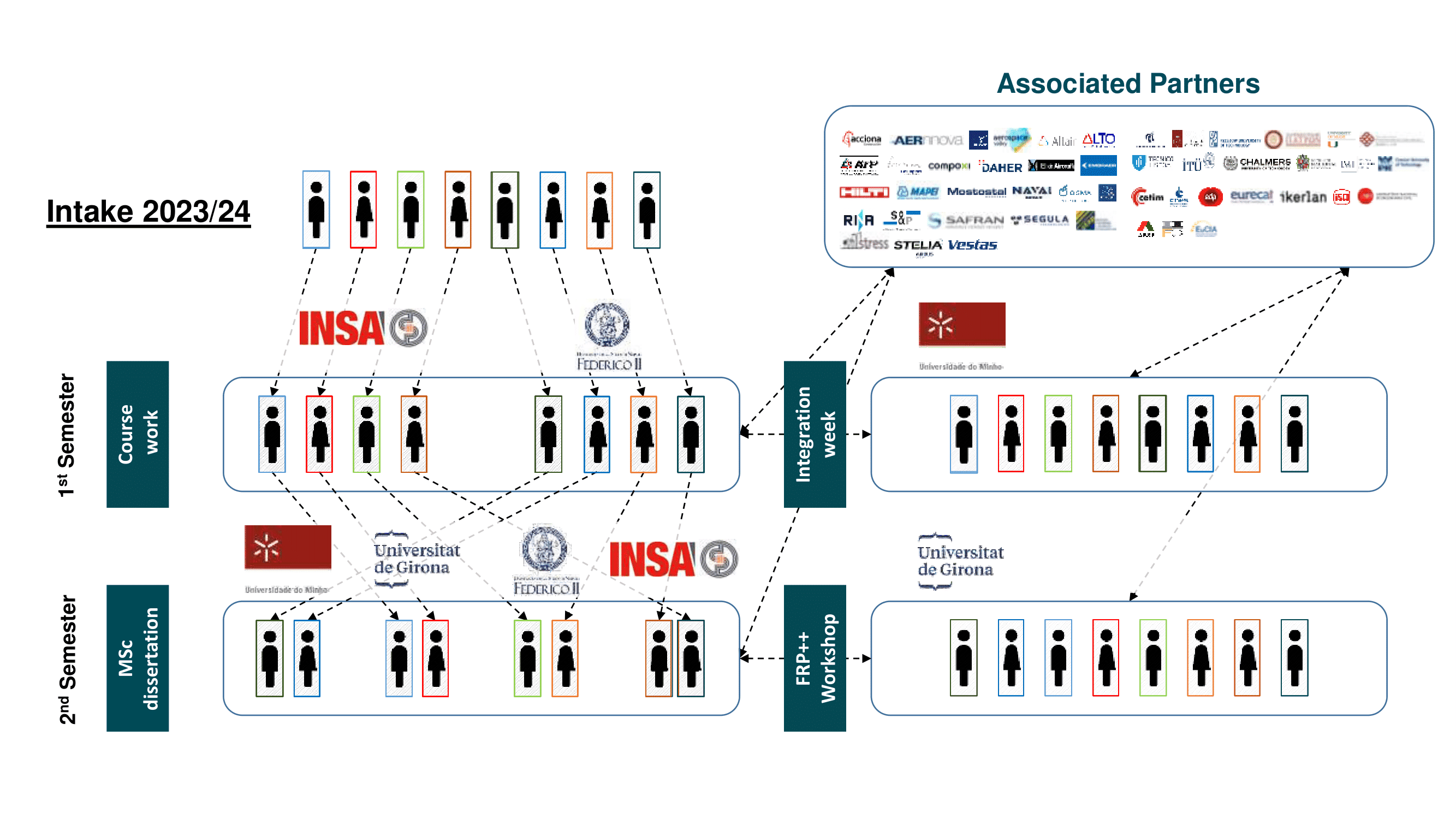

The six coursework units (1st semester), held on a rotating basis among partners, are concentrated in two countries each year and dissertation work (2nd semester) is divided by all involved institutions. It is mandatory that students carry out the entire coursework in one location and the dissertation in another location. The mobility track is based on students’ preferences taking into account an adequate balance between different institutions. The curriculum is exactly the same, no matter the student mobility track. The programme also includes the Integration Week (November) and the annual FRP++ workshop (May) where all students will meet together in Consortium members that do not host any coursework in this academic year.

The FRP++ mobility scheme allows students to visit the four involved partners. The full cycle of mobility is completed after 4 Master editions and will be started over again. The table and the graph below summarise the full mobility cycle, including coursework, MSc dissertation, Integration Week and FRP++ Workshop.

There are three compulsory and one optional physical student mobility: i) 1st mobility – coursework (Mandatory); ii) 2nd mobility – Integration Week (Mandatory); iii) 3rd mobility – dissertation (Mandatory); iv) 4th mobility – FRP++ Workshop (optional). While the Integration Week is financially supported by the Consortium, the students may need to support the physical presence at FRP++ Workshop – optionally they can also participate virtually (the participation is Mandatory either physical or virtual). However, local sponsors are perused to, at least, support partially the costs.

Academic year | Coursework | MSc Dissertation | Integration Week | FRP++ Workshop |

|---|---|---|---|---|

2022/2023 | UMINHO, UdG | ALL | UNINA | INSA/UT3 |

2023/2024 | UNINA, INSA/UT3 | ALL | UMINHO | UdG |

2024/2025 | UMINHO, UdG | ALL | INSA/UT3 | UNINA |

2025/2026 | UNINA, INSA/UT3 | ALL | UdG | UMINHO |

The FRP++ is a one year, full-time very intensive programme. The study programme is composed of seven course units (modules): i) five sequential units and ii) one project-based learning unit along the 1st semester (October to February) of 5 ECTS – 45 hours of lectures and 95 hours of independent student work each and, iii) one dissertation during the 2nd semester (March to July) of 30 ECTS – 45 tutorial hours and 795 hours of independent student work. The curriculum is the same, no matter the student mobility track:

FRP++1 (5 ETCS) Composite materials in the industry

Coordinator: Bruno Castanié

Description: The unit covers important topics on the composite materials in the construction and mechanical engineering. It includes critical aspects such as materials and processes, types, characteristics and processing of composite materials (including additive manufacturing – AM), adhesives and manufacturing process. Methods for assessing the properties of composite materials are introduced. The comparison between composite materials and traditional materials is also underline. Critical aspects associated to the computer aided simulation of composite of composite materials and structures are introduced, as well as critical aspects on their sustainability and life cycle analysis.

Main learning objectives:

- Get an overview about the use of composite materials in the industry

- Be able of selecting proper materials and processes for a specific application

- Understand critical aspects in terms of types, characteristics and processing of composite materials, adhesives and manufacturing processes

- Know the advantages and disadvantages of composite and traditional materials

- Understand the existing methods for assessing the properties of composite materials

- Understand critical aspects of computer aided simulation of composite materials and structures

- Be able to perform a life cycle analysis of composite materials and structures

FRP++2 (5 ETCS) Mechanics of composite materials

Coordinator: Norbert Blanco

Description: Unit covers important topics about the mechanical and structural behaviour of composite materials. It includes key aspects such as transversally isotropic elastic behaviour, laminates, failure and damage, delamination and long-term effects. The analysis of composite materials in terms of structural behaviour with finite element simulations is also introduced. The combination of these tools provides the basis for the design process with composite materials for construction and mechanical applications.

Main learning objectives:

- Get an overview about the mechanical and structural behaviour of composite materials

- Be able to infer the composite mechanical properties from constituent ones

- Be able to predict the structural behaviour of composite laminates

- Be able to anticipate damage and failure in composites and predict post-failure behaviour

- Understand critical aspects of hygrothermal, long-term and ageing effects on composite materials

- Be able to simulate the mechanical behaviour of composites with Finite Elements Analysis

FRP++3 (5 ETCS) Advanced modelling and computer aided design

Coordinator: Pere Maimi

Description: Unit aims to complete the knowledge from unit FRP++2, providing to the student the capabilities to perform advanced analysis of the mechanical (and/or multiphysics) performance of composite structures. The syllabus also aims to provide knowledge on the optimal design of a composite component, mainly laminates, and the definition of the manufacturing plan (including discussion on AM). Optimization of composites structures is achieved with computer aided. Some examples of how a software can help optimizing the processing, manufacturing and mechanical behaviour of composite materials are provided.

Main learning objectives:

- Be able to make use of computer software to analyse various aspects of composite structure design and process

- Be able to analyse the nonlinear behaviour of composites structures accounting for both geometric and material nonlinearities

- Be able to define the scale of the analysis models and perform simulations at different scales

- Understand the modelling of manufacturing: thermocinetics, thermochemical and thermomechanical modelling

- Be able to design a composite component and prepare the cutting plan understand critical aspects on optimization of the design of the composite component

- Be able to perform a life cycle analysis of the designed composite component.

FRP++4 (5 ETCS) Design of structures with FRP materials

Coordinator: José Sena Cruz

Description: The syllabus covers important topics on the design of structures with FRP materials. Initially it includes the basis of design of structures with FRP materials transversal topic. Then, all the detailed aspects on the design of reinforced concrete structural elements with FRP, as well as on the design of profiles and sandwich structures, as well as connections and joins is introduced, including GAP method, according to the most recent codes (e.g. CEN TS). Afterwards, the critical aspects on the assessment of life cycle of structures designed with FRP materials are dealt with.

Main learning objectives:

- Get an overview about the protocol followed in the design of structures with FRP materials

- Be able to design reinforced concrete structural elements with FRP bars

- Be able to design pultruded FRP profiles and sandwich structures

- Design and machining innovative composite structures

- Be able to design joins and connections

- Be able to perform a life cycle analysis of structures designed with FRP materials

FRP++5 (5 ETCS) Inspection, diagnosis, repairing and strengthening of existing structures

Coordinator: Marco Di Ludovico

Description: The syllabus covers important topics on the inspection, diagnosis, repairing and strengthening of existing structures. Prior the intervention in the existing structures, fundamental aspects on the inspection and diagnosis of existing structures are introduced. Then, main aspects on the strengthening of existing structures with composite materials (basis of design, strengthening, installation, control and maintenance) are presented, following recent codes/guidelines (e.g. ACI, CNR, ENs, fib). Similar strategies are used for introducing the repairing of existing structures. The critical aspects on the assessment of life cycle of structures designed with FRP materials are given. Finally, case studies are introduced in order to highlight all the involved issues on inspection, diagnosis, repairing and strengthening of existing structures.

Main learning objectives:

- Be able to perform inspection of existing structures

- Be able to perform diagnosis of existing structures

- Be able to design solutions in composite materials for the repair of existing structures

- Be able to design solutions in composite materials for the strengthening of existing structures

- Be able to develop life cycle analysis on repairing and strengthening existing structures

FRP++6 (5 ETCS) Integrated project

Coordinator: Joaquim Barros

Description: The unit includes two comprehensive case study projects, field visits and seminars. The two case study projects are i) the development of a project which includes analysis, design and detailing of complex structures in composite materials used in civil and mechanical engineering, and ii) the analysis, design and detailing of repairs and/or strengthening in complex structures in composite materials used in civil and mechanical engineering. The second project will be developed among the students of the two involved coursework hosting Institutions, while first one will be developed only with students of the local hosting Institution. Skills and competences will be ensured during the curricular unit period, due to the teaching methodologies adopted. The unit is based in a specific learning model, where the development of an integrated project with composite materials is pursued. This learning model allows students to develop their capacity to interrelate knowledge and seek for practical solutions applied in real case studies. On the other hand, since this curricular unit runs throughout the semester, it will take advantage of the knowledge collected in the other curricular units, allowing to generate additive knowledge.

Main learning objectives:

- Get additional knowledge in civil and mechanical engineering with composite materials

- Be able to develop an integrated project of a structure with composite materials

- Be able to develop an integrated project on the repairing and/or strengthening of an existing structure with composite materials

- Develop transversal skills and competences.

FRP++7 (30 ETCS) Dissertation

Coordinator: Andrea Prota

Description: It is the objective of this curricular unit that students develop search work on concepts, models and instruments related to the research work to be investigated. This research work will allow the development of the original research work, in which the student will have to integrate the knowledge acquired throughout the course, deal with complex issues, in multidisciplinary contexts, developing solutions and reflections on the subject under study. At the end the student shall proceed to a synthesis work in order to write the dissertation. During the development of the dissertation, internships at Associated Partners facilities are whenever possible, desirable.

Main learning objectives:

- Plan the research work

- Develop the research work

- Present the research work in dissertation format