Professional Perspectives

Why composites are relevant and why we should care?

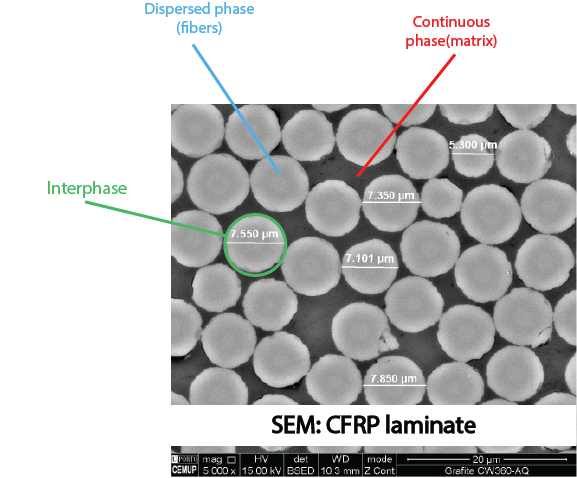

Composite materials, also named as composites or Fibre Reinforced Polymer (FRP) materials, are materials composed of two phases, namely the reinforcement (fibres) and the (polymeric) matrix (see figure below as example of a scanning electron microscopy of a Carbon FRP – CFRP).

Carbon, glass, aramid and basalt are the most used fibres, while polyester, vinylester or epoxy are normally used as matrix. The fibres, with higher resistance, are responsible for the stiffness and strength of the composites, whereas the matrix, with lower resistance, is responsible for the transfer of stresses and protection of the fibres.

Composites have been successfully used in the aerospace, construction and infrastructures, automotive, wind energy, defence, maritime and sports and recreation, among others (see some examples below), due to the unique characteristics, namely, excellent mechanical properties, high durability (corrosion resistance), lightness, ease of use and virtually endlessvariety of shapes. Furthermore, several studies have proved that the use of Composite Materials yields to more sustainable and resilient solutions, compared to traditional materials, e.g. metallic alloys or concrete.

A monocoque fully made of composites

The longest (107 m) wind rotor blade made of composites

Many aircrafts are made mostly in composites

Rehabilitation of many bridges with composite materials

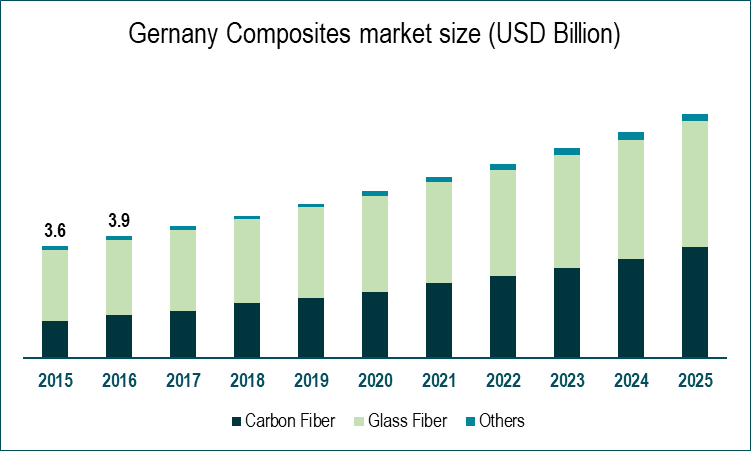

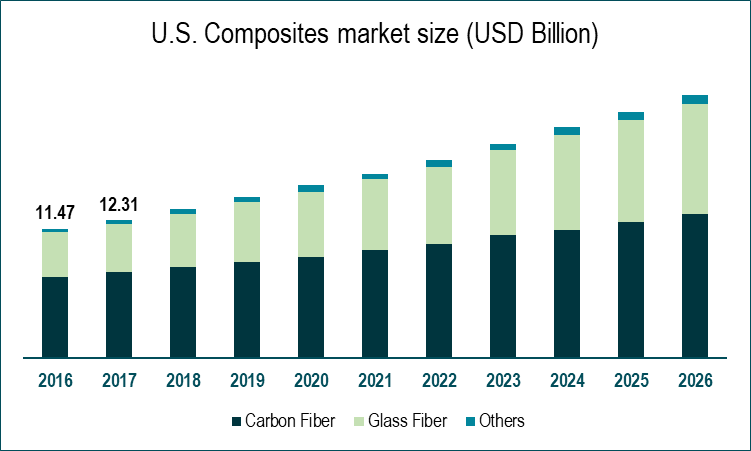

Over the last decades the composite materials industry has grown and, with the increasing demands from various industries like construction, aerospace, energy, defence, and automotive and transportation, it is expected to continue to grow in the foreseeable future. For instance, in 2019 the global composite market was estimated at USD 89.0 billion and it was expected to expand, with a compounded annual growth rate (CAGR) of 7.6% until 2027. In Europe, the composite market size was worth USD 16.6 billion in 2018 and was estimated to register a CAGR of 7.5% from 2019 to 2025. Figures on the right side shows the composites market size, by product, of Germany and United States. The actual distribution of the main composite market is: 27% China, 26% North America, 21% Europe, 19% Other Asia, 4% Middle East/Africa and 3% South America.

According to JEC Observer of global composite market 2019-2024, while in marine, energies and electronics, with high rate of penetration, has reaching an almost plateau, in the construction, aeronautics, defence and automotive there are a great potential for further penetration. The main reasons for this growth are: i) the increasing need for lightweight materials in the aerospace, defence and automotive (including electric and connected / autonomous cars) industries – diminishing the mass in the transportation sector is a key issue for reducing CO2 emission (e.g. minus 100 kg in a car means about minus 10g/100 km of CO2); ii) the need for corrosion-resistant materials and chemicals in the construction, new designs and “green” architecture (e.g. low energy consumptions), pipeline and tank industries and infrastructure upgrades (e.g. bridges); iii) electrical resistivity and high need for flame retardant materials in the electrical and electronics industry.

Composites present higher strength-to-weight ratio than that of steel and aluminium. By saving in weight for a given level of strength makes the use of composites vital in the transportation industry. Environmental regulations worldwide regarding emission standards, namely in North America, Europe, and China are the major driving factors behind the introduction of more lightweight and fuel-efficient composites in transportation. The main reasons for this grow are the reduction in the weight and the resistance to corrosion. Additionally, the costs of maintenance aircrafts made from composites are lower when compared with aircrafts made with traditional materials. Composites have inherent resistance to corrosive impacts of water, salt, chemicals, thus, being attractive options in the marine world and in suitable replacements for metal structures that are exposed outdoors (tanks, piping, cooling towers, railcars for chemical transport and much more) or buried underground.

In the developed countries impressive infrastructure of concrete, wood and steel can be found, with deteriorating at an alarming rate. The annual cost of metallic corrosion alone, worldwide, is incredible high. Considering the cost of maintenance, prevention, replacement of parts and interruption of services due to maintenance, the World Corrosion Organization, according to some estimates, the annual cost of corrosion worldwide is US$2.2 trillion, more than 3% of the world’s gross domestic product. The US Department of Defence has estimated the annual cost of corrosion in military applications alone at more than US$10 billion per year. Furthermore, the US Federal Highway Administration (FHWA) estimates that to eliminate the US nation’s bridge deficient backlog by 2028, US would need to invest $20.5bn annually (more than 230,000 US bridges require structural rehabilitation). On the other hand, according to the European Construction Industry Federation (FIEC), in 2019, investments in rehabilitation and maintenance activities represented 28% (EURO 371 billion) of the total investment in construction. Furthermore, for the EU27, investments in rehabilitation and maintenance continued their growth path.

Other emergent markets are the ones related to the end-of-life, recycling and reuse. This brings new challenges to the composites sector. For example to prove how serious this topic is, the end-of-life regulations in the European Union, granted, an extreme example, already require that 95% of automobiles manufactured in Europe be recyclable.

Considering these aspects, professionals on structural composites are need to tackle the market needs with expertise/skills in i) new products (e.g. new lightweight cars, aircrafts, construction solutions), ii) extend the service life of existing products (e.g. repairing, strengthening) and also iii) with concerns about sustainability. The EMJM FRP++ curriculum addresses these key areas, training professionals with the proper expertise/skills to play a decisive role in this market.